- 16526 Air Center Blvd, Houston, TX 77032

- |Contact Us

Shipping Container Insulation in Houston, Texas

When it comes to withstanding extreme temperatures, your shipping containers could benefit from insulation services. Because it is becoming increasingly popular to insulate the interior of storage containers, there is a number of methods you can choose from as you prepare for shipping cargo container insulation. At IBP Houston, we can help you improve the energy efficiency, keep corrosion and mold issues at bay and improve the overall condition of your shipping container.

Give the experts at IBP Houston a call at 281-653-8382 if you’re ready to begin your insulation project, or fill out a contact form today!

Cargo Container Insulation Methods

Because a shipping container may be traveling through a variety of different temperatures, it is important to design your insulation plans around the potential climates. Say your modular container will be in a cold climate—it may be wise to consider the benefits of spray foam insulation, which can create a seamless vapor barrier against wetness and condensation. If your container will be traveling to a warmer area, you may want insulation for a cargo container to keep it cool on even the hottest days of the year. No matter your goal, there are a myriad of insulation options for your shipping container.

Spray Foam Insulation

Commonly acknowledged as one of the most efficient forms of insulation, spray foam insulation can offer the highest insulation value. The spray foam is spread across the entire surface of the cargo container walls, leaving no openings between the insulation material and the wall of the container. Applied wet, this insulation expands into thick foam that will fill even the smallest cavities and crevices in the wall of your shipping container. Known as an air-sealing solution, spray foam insulation can help your shipping container avoid problems with condensation and moisture infiltration.

Fiberglass Insulation

Made of tiny glass fibers, this form of insulation can be used to insulate shipping containers. During the process of installing fiberglass insulation, sections are cut and fit inside a wood framed interior, which may leave openings between the insulation and the container’s wall. However, it is possible to put a moisture barrier between the wall of the container and the insulation in order to keep condensation out. The team at IBP Houston installs both batt and blown-in fiberglass insulation depending on your needs.

Rigid Foam Insulation

Varying in width and length, the foam panels used in rigid foam insulation can be cut to fit the needs of your shipping container. The installation process involves either gluing the panels directly to the container’s walls or screwing the panels into the flat bar mounted to the walls of the container. This type of insulation can save you space, freeing up inches of sidewall and ceiling space.

Insulation Installers in Houston, Texas Area

No matter the form of insulation you are hoping to implement for your cargo container, the professionals at IBP Houston can help. As a part of the Installed Building Products family of companies, we have access to top products, pricing and training in the industry. Our experienced and dedicated experts can help you decide which type of insulation is best for your needs. Learn more about our commercial services by calling us today!

Ready to insulate your modular container? Call today at 281-653-8382 or fill out a contact form!

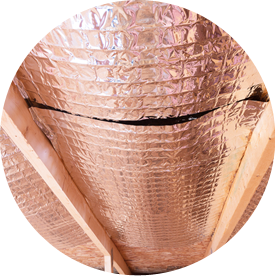

We can help keep your home cooler and more comfortable with an attic radiant barrier.

Environmentally friendly and effective, cellulose works well in homes and buildings.